What is your role and hoW did you arrive at your current position? After studying physics in Greece and completing an MSc in Photonics in Scotland, I joined M Squared as a Laser Technician. I undertook Laser Engineer training With the company, and after my first year, I qualified as Laser Manufacturing Engineer, Which is my current role. It involves building, testing, shipping and installing one of the company’s laser systems. What time do you Wake up? I Wake up at 6:50 in the morning. When do you start? I usually arrive at Work around 8:30.

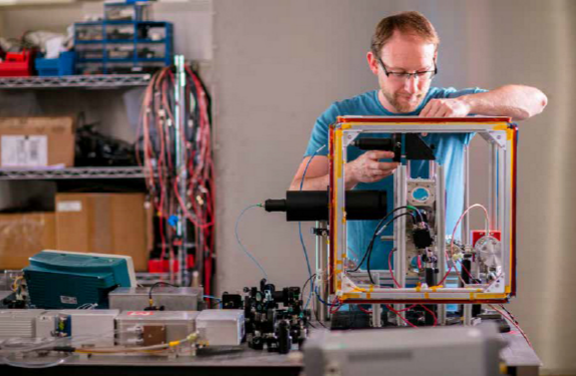

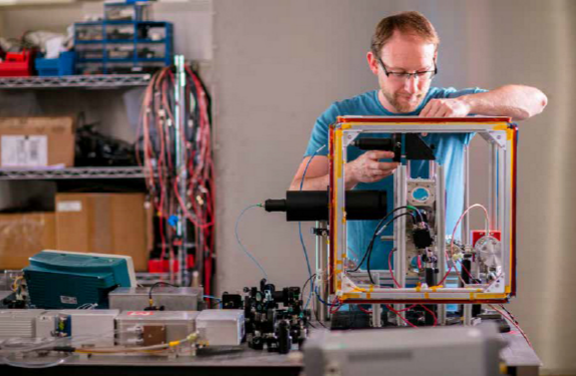

What is the first thing you do when you arrive at work? I perform checks on the system I was working on the previous day so that I can update the rest of the production team about its build progress during the morning meeting. What attracted you to your career? When I was studying physics for my undergraduate degree, I developed an interest in lasers. After graduating, I was keen to move into this area of engineering so that I could work on photonics products. What have been your biggest challenges in this role? Learning how to build such an advanced laser system is characterised by a steep learning curve which has always been the biggest challenge. Moreover, because our products are constantly evolving, as soon as you familiarise yourself with one aspect of production you have to learn something new, which keeps things interesting. Describe your workspace. I spend most of my time working in the booths of the production area where our laser products are being built and tested. Each of these production booths has a large bench with an optical breadboard on top. The space on and around the benches is populated with a variety of opto-mechanical and electro-optical hardware. It will look familiar to anyone that has worked in a photonics laboratory. What kind of tools do you work with? Building one of our laser products requires the use of a variety of optical, mechanical and electrical equipment that ranges from general purpose optics like mirrors and lenses to highly specialised optoelectronic test equipment. Who do you interact most with? I interact the most with the rest of the production team which comprises engineers from a range of different disciplines. I also get the chance to meet some of our customers which usually are scientists or engineers working on some exciting projects. How often do you get out of the office? My role requires some travel, mainly for installing or servicing the company’s laser products throughout the world. On average, I spend around a week each month away from the office although this may vary according to production needs. What do you most look forward to each day? I look forward to working with a group of dedicated engineers and scientists from different backgrounds that are passionate about developing and building innovative laser products. What or who inspires you? What inspires me most is being part of a team that designs and manufactures cutting-edge photonics systems that will be used to enable advances both in science and in the commercial world. What do you do for lunch? Most days I bring my lunch to work. Sometimes I get a takeaway, and occasionally I eat out with my colleagues. Describe your best day at work to date. I cannot single out any particular day as my best day at work. A great day at work for me is when I manage to overcome a technical problem or when I learn something new and exciting. How does the working day end? I take notes about the status of the system I was working on. Before leaving I make sure that everything is properly turned off and my production booth is reasonably tidy. What time do you get home? Depending on traffic, I usually arrive at home around six.

Phone +44 (0)141 945 0500

Head Office

Phone +1-617-401-2368

USA

Phone +44 (0)1483 685170

M Squared Life