What is your role and how did you arrive at your current position? I studied physics at the University of St Andrews and my final year project focussed on building lasers. I thoroughly enjoyed that work, so I knew I wanted a job in laser production after I graduated. I began work at M Squared as a Graduate Laser Engineer building Equinox lasers, soon becoming a Laser Manufacturing Engineer after a period of training. As the Equinox team grew in number, I was promoted to Equinox Manufacturing Product Lead - it's an excellent team. What time do you wake up? I usually get up around 8 am. When do you start?I start work around 9 - it's quite a fast turnaround from wake up to working. What is the first thing you do when you arrive at work?

I start my day with a cup of coffee, which is promptly followed by a morning meeting with the Equinox manufacturing team as we get organised for the day ahead.

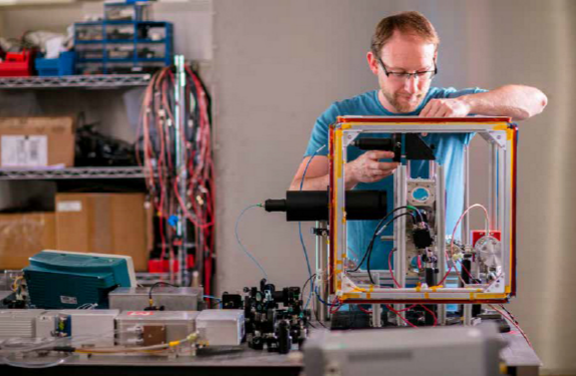

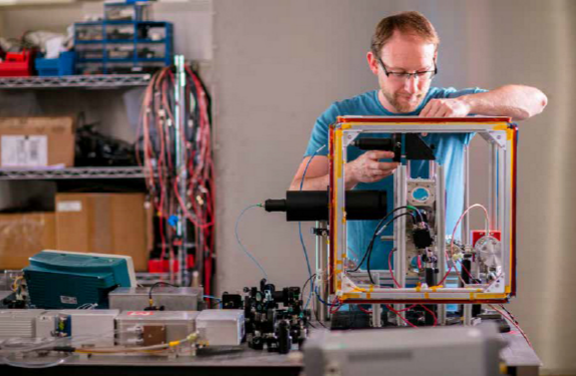

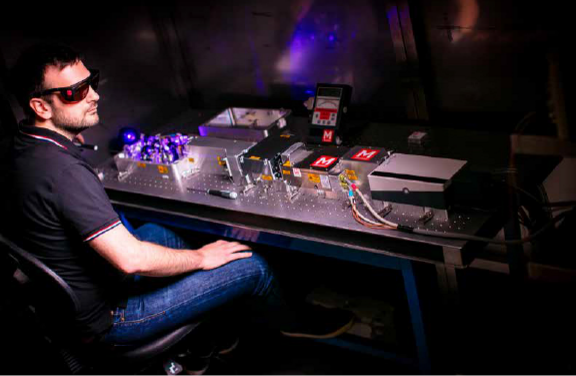

What attracted you to your career? I see physics as an extension of the problem-solving that I have always enjoyed. I loved puzzles growing up. My mum tells me it all started with a jigsaw puzzle that I had when I was a child - I would solve it over and over again. Within physics, it was always the lab work that I especially enjoyed, doing all sorts of interesting experiments. It's the practical aspect of physics that led me to the work I do today. What have been your biggest challenges in this role? I think I faced my biggest challenge when I first started working at the company. The learning curve for building a new type of laser as well as working in a production environment was steep. However, I enjoyed the challenges as it has helped me to develop both personally and professionally. Describe your workspace. The defining feature for me is the very open workspace. All engineers have individual booths to work in, but the spaces between them are very light and open. This layout makes it easy to find and communicate with my colleagues, and it creates a nice working environment. Within the booths, there are large breadboards to build the lasers on with full sets of tools and equipment. What kind of tools do you work with? I require all sorts of tools and equipment to build and test Equinox lasers ranging from screwdrivers, alignment tools, tools for cleaning optics to more advanced optoelectronic equipment for testing the lasers. Who do you interact most with? Most of my interaction is with the production engineers - we support each other every day with our builds. How often do you get out of the office? My job is very location-based - I am never far from a breadboard, so I don't need to leave headquarters very often. What do you most look forward to each day? I look forward to coming in and building lasers. Every laser is different with different problems to overcome making each a fun challenge. I feel lucky to have a hands-on job that keeps me active during the day. What or who inspires you? My parents inspire me as they have always been very motivated and hardworking. One of my dad's favourite quotes is 'work the problem' which I'm reminded of very often in this job! What do you do for lunch? I mostly go home for lunch. Out of all of the staff, I believe I have one of the shortest commutes; it's a lovely 10-minute walk. Describe your best day at work to date. I have had many great days at work, but if I had to choose one, I would say that finishing my first laser for the company was a great feeling. How does the working day end? I tidy up my booth because coming into a clean workspace in the morning puts me in a good headspace for the rest of the day. What time do you get home?Around 5.40 pm, thanks to my 10-minute commute.

Phone +44 (0)141 945 0500

Head Office

Phone +1-617-401-2368

USA

Phone +44 (0)1483 685170

M Squared Life